Views: 19

SLS prototyping technology was first proposed by Carl Ckard of the University of Texas at Austin in 1989 in his master's thesis. Later, DTM introduced Sinter Sation, a commercial production equipment of the process in 1992. Over the past decades, Austin and DTM have done a lot of research work in SLS prototyping technology, and have achieved fruitful accomplishments in equipment development, technologies and material development. EOS company in Germany has also done a lot of research work in this field, and developed a series of corresponding forming equipment.

There are also many units in China to carry out the related research in SLS prototyping technology, such as the Mechanical College of Xi'an Jiaotong University, the National Engineering Research Center for Rapid Prototyping and the Rapid Prototyping Engineering Research Center of the Ministry of Education and so on. And they have also made many important achievements, such as RAP-I laser sintering rapid prototyping system developed by Nanjing University of Aeronautics and Astronautics and commercialized equipment of AFS-300 laser rapid prototyping developed by Beijing Longyuan Automatic Prototyping Company.

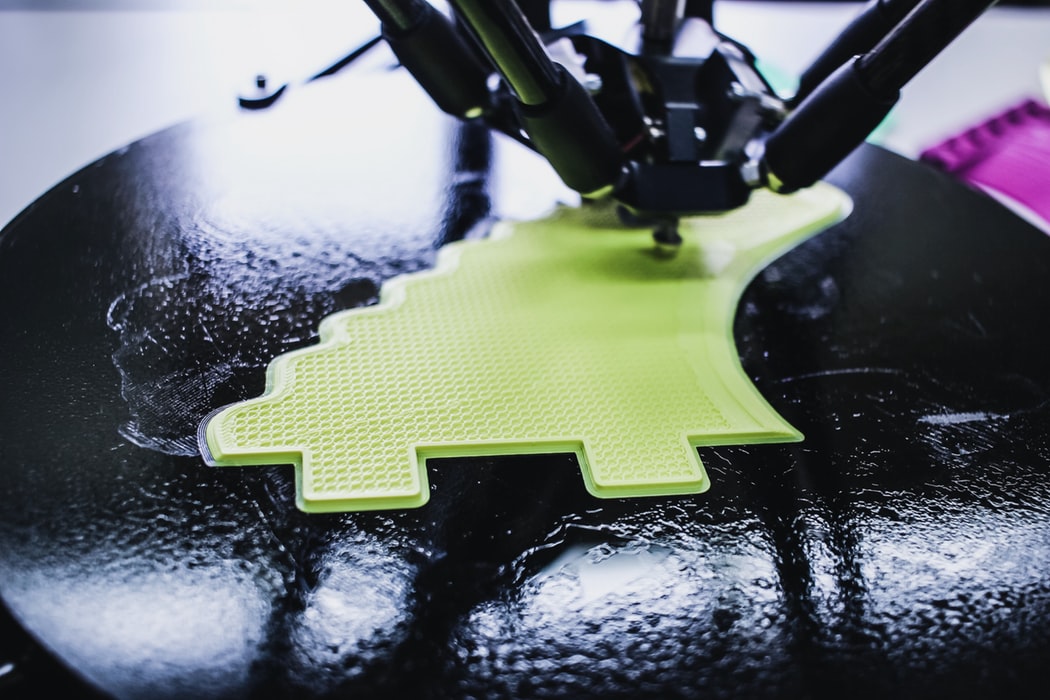

SLS prototyping technology is a method of selectively layering solid powder by laser and superimposing the solidified layer formed by sintering to produce the required shape of parts. The whole process includes the establishment of CAD model, data processing, powder laying, sintering and post-processing.

Compared with other rapid prototyping methods, the most outstanding advantage of SLS prototyping technology is that it uses a wide range of forming materials. Theoretically, any powder material that can form interatomic bonding after heating can be used as SLS forming material. The materials that can be successfully processed by SLS include paraffin, polymer, metal, ceramic powder and their composite powder materials. SLS is more and more widely used because of its characteristics of many kinds of forming materials, saving material, wide distribution of performance of forming parts, and no need to design and manufacture complex support systems.

However, SLS prototyping technology is a very young manufacturing field, which is not perfect in many aspects, such as low strength, low precision and poor surface quality of three-dimensional parts. SLS process involves many parameters, such as physical and chemical properties of materials, laser parameters and sintering process parameters and so on, which affect the sintering process, forming accuracy and quality. In the forming process of parts, due to the influence of various material factors and technological factors, various metallurgical defects will occur in sintered parts, such as cracks, deformation, pores and uneven structures .

In short, in rapid prototyping technology, SLS technology is a hot research topic. It is difficult to produce parts of high strength by traditional cutting methods. And it is very important for the wider application of rapid prototyping technology to realize the direct sintering of parts with metals with the high melting point. We believe that with the mastery of the forming mechanism of sintering metal powder by laser, the acquisition of the best sintering parameters of various metal materials and the emergence of special rapid prototyping materials will enter a new stage.